Centrifuge Systems Mechanical Maintenance Repair

DECANTOR MAINTENANCE

What is a decanter?

Decanter ; It is the name given to the solid-liquid separator used in the separation of liquids where the volumetric ratio of solid particles is 40-50%. It provides this separation process with the drum rotating at high speed and the helix rotating at different speed on the same axis with the drum and the drive group that adjusts the speed difference.

In decanter centrifugal product handling application, decanter maintenance is crucial when it comes to running an efficient, profitable and safe working process. We offer gearbox, balancing services, complete replacement of used equipment, replacement and repair of wear components and much more decanter maintenance services that help extend the life of decanter centrifuges for all makes and models and reduce maintenance costs.

Decanter Maintenance Services;

Bowl Maintenance

- Replacement of Bearings and seals

- Repair or replacement of worn components

Scroll Maintenance

- Wheel balancing

- Repair of scroll leaves

- Wolfram carbide coating of scroll sheets

- Replacement of feed zone components

Gearboxes Maintenance

- Inspection and wear analysis

- Repair or replacement of worn components.

- Replacement of all lubricants and seals

Inspections and Quoting :

- With a comprehensive inspection process, the requirements

of the equipment are documented with photographs and presented to the

customer before implementation

- Reports are kept on file, maintain a history of

repairs for each piece of equipment

Service and Conversion

- On-site maintenance services

- On-site troubleshooting

- Customer specific maintenance programs

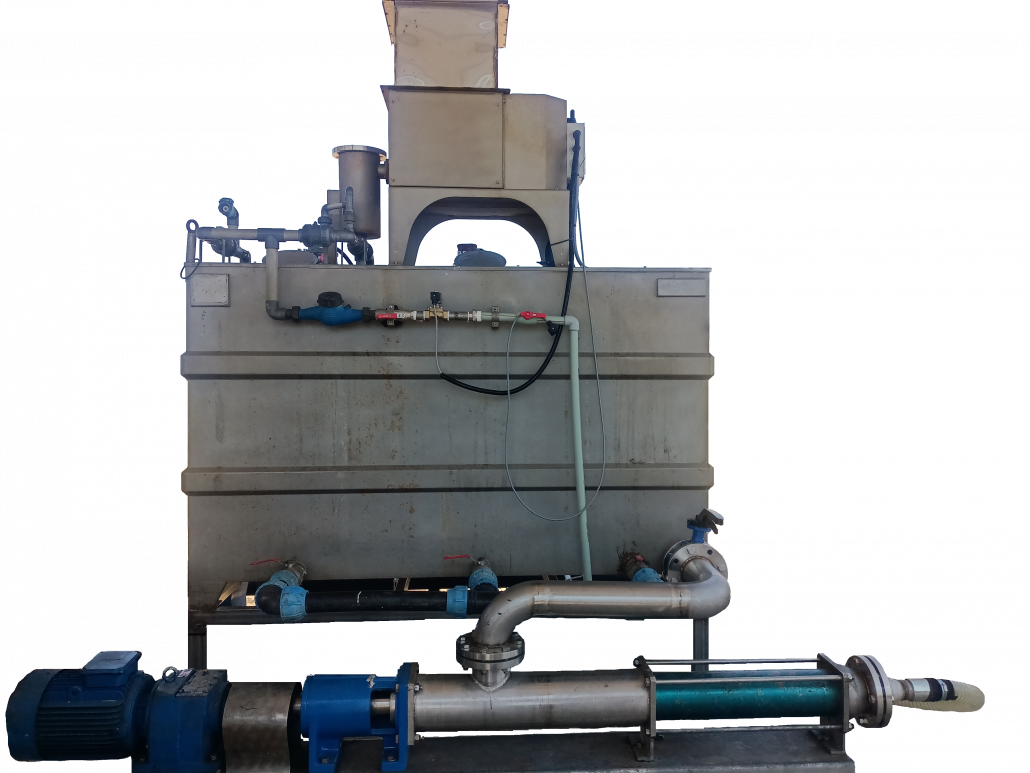

POLYMER UNIT

The Polymer Unit, which occupies an important place in the sludge processing units of waste water treatment plants, is used in the sludge thickening phase. Solid and liquid sludge should be fed with polymer to provide a better dewatering performance.

Maintenance Services

- Polymer tank maintenance and overhaul

- Adapting to the existing program in line with customer demand

WASTEWATER TREATMENT EQUIPMENT

- Sludge Pump

Polymer Pump

Polymer Pump- Sludge Pool Mixer

- Scraper

- Conveyor

SEPERATOR MAINTENANCE

There are various ways of separating liquid phases and solids from liquids. The two most common technologies are centrifugal separation and filtration. Decanters and disc stack separators are centrifugal separators. In many processes, both decanters, disc stack separators and filters are used at different stages of the process to achieve the required separation result.

A planned maintenance program can keep your equipment running efficiently and effectively, increasing your uptime and machining quality while reducing future repair costs and downtime. We offer services that help extend the life of separator centrifuges for all brands and models, reduce maintenance costs, replace wear components, repair and much more.

Maintenance Services

- Bowl disassembly and inspection of centripetal pumps and disk stack

- Cleaning the discs

- Repair or replacement of worn components

Service and Conversion

- On-site maintenance services

- On-site troubleshooting

- Customer specific maintenance programs

Inspections and Quoting :

- With a comprehensive inspection process, the requirements

of the equipment are documented with photographs and presented to the

customer before implementation

- Reports are kept on file, maintain a history of

repairs for each piece of equipment